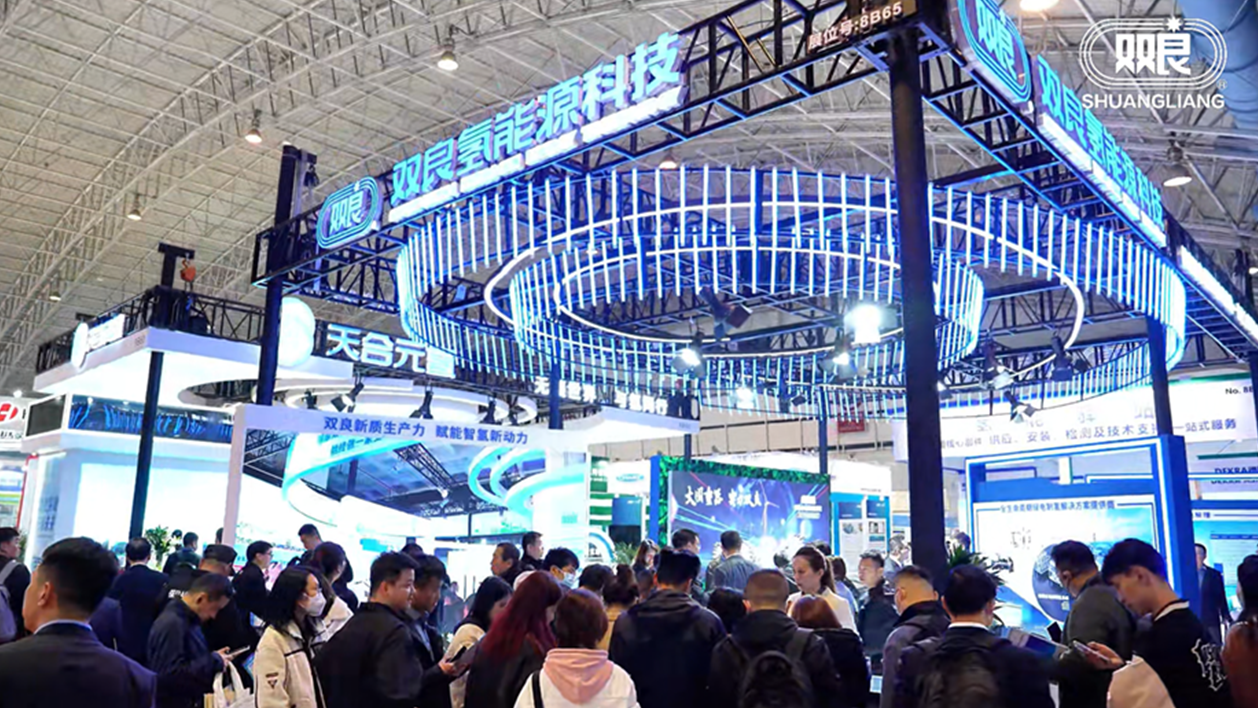

Shuangliang Green Hydrogen

Relying on more than 40 years of mechanical manufacturing experience,

Shuangliang started hydrogen production system research since 2015. In Sep

2022, Shuangliang launched 1st unit 1000NM3/h AWE electrolysis stack and BOP

system. In Oct 2023, Shuangliang released new generation 10MW electrolyzer

with world leading performance figures in the industry.

Alkaline Water Electrolysis Equipment for Hydrogen Production

More adaptable to renewable power.

Learn More

Advantages

-

More Professional

The hydrogen production system adopts core components such as pressure vessels, BOP units and catalysts that are completely designed and manufactured in-house. -

More Secure

The electrolyzer adopts intrinsically safe design to achieve triple insurance, eliminate hydrogen and oxygen mixture, no risk of leak and fire. -

More Longevity

The electrolytic cell adopts advanced materials, processes, and design, with a service life of up to 20 years. -

More Intelligent

The electrolyzer adopts advanced diaphragm, catalyst, structural technology, and the energy consumption can be as low as 3.993 kWh/ NM3H2@2500A /m2. -

More Efficient

The hydrogen production system adopts the advanced Shuangliang intelligent system WONDER CLOUD/OS digital platform, which can ensure the system operates under optimal conditions.

Applications

With its innovative design in safety, longevity, and efficiency, Shuangliang

large size hydrogen production system can excellently serve the hydrogen

demand in different industries, such as chemical, transportation, refinery,

and metallurgy, etc.

-

ChemicalCurrently the most applied industry for green hydrogen.

-

RefineryGreen hydrogen is to be widely used in refinery industry in terms of replacement of gray hydrogen.

-

SteelGreen Hydrogen will play significant role in the carbon emission reduction in steel industry.

-

TransportationHydrogen as driving energy has big potential in transportation sector.

(1)(1)-fb1d9d2ef9e9490f9e1c3906ca9586f4.jpg)