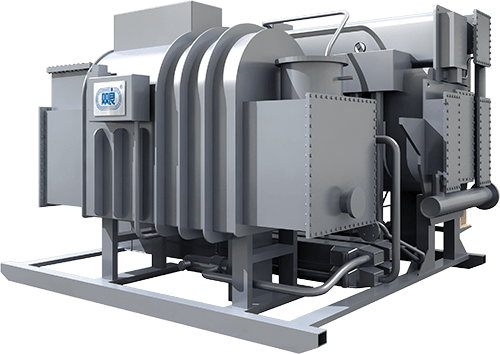

The flue gas operated LiBr absorption chiller / heater is an energy-saving equipment driven by the waste heat of flue gas, in most cases, exhaust gas from engine, turbine or other combustion equipments, to produce chilled water and/or hot water.

The main application of flue gas LiBr absorption chiller/heater is in co-generation or tri-generation, for comfort or process cooling/heating. And according to the site condition & user's requirement, flue gas unit can be designed to work with supplementary heat source to achieve more flexibility, such as:

Flue gas + engine jacket water (supplementary heat): it can recover maximum waste heat from engine, provide maximum cooling capacity and achieve overall energy efficiency as high as 85%.

Flue gas + direct fired burner (supplementary heat): direct fired burner can be used as back-up source in case flue gas is not available or not enough to generate enough cooling capacity.

Flue gas + steam (supplementary heat): it's suitable for any site with surplus steam supply. Steam can provide extra cooling capacity or back up the energy input when flue gas is not available or not sufficient.

Flexible combinations like flue gas chiller + jacket water + burner, flue gas + jacket water + steam and etc are also available.

Specify your requirements for tailored services (optional).