With its great success in air cooled condenser (ACC), 40yearsin vacuum heat exchanging and 20 years in dry cooling technology, Shuangliangis now entering to a new application - circulating water cooling for various industries. The newlydeveloped SGSL series hybrid cooling tower is aiming at saving waterconsumption for different industries, like food and beverage, pharmaceutical,steel, chemical, electronics, etc.

Traditional cooling methods for industrial circulating water

A large amount of heat is produced in the production processof industrial field, which needs to be cooled by circulating water coolingsystem. The traditional cooling method is open circle water cooling tower.

Problems with traditional cooling methods

· High water consumption(1.5%~1.8% of circulating water), serious waste of water resources, not incompliance with environmental policy;

· High operating waterconsumption and sewage treatment cost, poor economy;

· Winter operation producesa large number of white fog, become the carrier of haze, and ‘culprit’ of theHaze;

· Winter white fog formssnow, frost microclimate, resulting in safety risks.

With the tightening of environmental protection policies,traditional circulating water cooling methods will be replaced. Shuangliang'senergy-saving, water-saving and mist-eliminating industrial circulating watersystem aims to achieve the dual benefits of environmental protection andeconomy.

1.Hybrid Cooling Tower

Structure

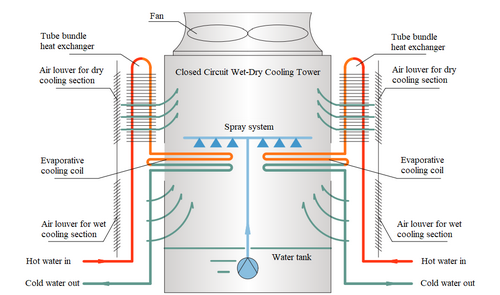

Combination of the air cooling radiator (finned tube)and evaporative cooling coil (smooth tube) in one cooling tower with novelstructure design The heat dissipation of the dry cooling section is verticallyarranged outside the tower, and the evaporative cooling coil section ishorizontally arranged inside the tower. Both sections work in series at waterside and in parallel at wind side.

Function

· Water saving

hybrid cooling tower operates in seasonalcycle with two main modes: Winter mode and Summer mode.

In summer, the main operating condition isto meet the cooling water temperature by opening the wet cooling section airlouver and closing the dry cooling section air louver to increase the windspeed through the wet cooling section, give full play to the cooling capacityof evaporative cooling in summer and meet the water temperature requirements.In winter, the main operating condition is mist-elimination and water saving byturning down the wet cooling section air louver and turning up the dry coolingsection air louver to increase the wind speed through the dry cooling section,give full play to the dry cooling capacity, and achieve the maximum watersaving.

What about in Spring and Autumn? It will bean inter-state between Summer and Winter mode, i.e., the air louver openness ofboth sections are well manipulated by PLC or DCS automation system to guaranteethe designed cooling water temperature, and saving water as much as possible atthe same time.

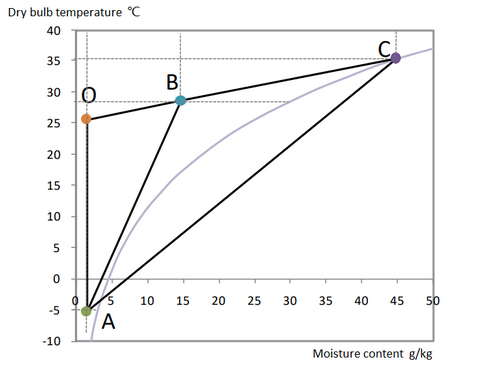

· Plume abatement

The circulating water enters the tubebundle in the dry cooling section for cooling and then enters the wet coolingsection for cooling. The high-temperature and high humidity air (state point C)generated by evaporative cooling in the wet section is mixed with the heateddry and hot air in the dry section to reduce the moisture content. It isdischarged after reaching state B. the mixing line (BA line) does not intersectwith the saturation line to realize mist elimination. This technical route caneliminate fog all year round.

Main Features

01/ Combined aircooling and evaporative cooling technology

Air cooling and water cooling areintegrated, and the switching and joint operation of air cooling and water coolingare used to ensure the stability of outlet water temperature and achieve theeffect of water saving and mist elimination. The economic benefits of watersaving are considerable and the benefits of environmental protection areobvious.

02/ L-type dryand wet combined system

The air cooling and water cooling adopt theL type layout of the invention patent: the air cooling section is arrangedvertically outside the tower, and the water cooling section is arrangedhorizontally inside the tower. The circulating water is cooled by the aircooling section first, and then by the water cooling section. The whole processis in the L type.

03/ Low thermalresistance and high heat transfer coefficient

The heat transfer surface of the fin of theair-cooled tube bundle is slotted to strengthen the turbulence, and the heattransfer coefficient is high. The fin is closely combined with the base tubeafter expansion, and the thermal resistance is low. For long-term operation,because the spring effect is still tight, the heat exchange efficiency decaysslowly.

04/ Optimizedpipeline process design

The double-flow counter cross flow can makethe heat-transfer coefficient higher.

05/ Low windresistance and low power consumption

The fins between each row of air coolingtube bundle are continuous, and the wind resistance of air-cooled tube bundleis low. The air cooling tube bundle is vertically arranged outside the tower,the air cooling section and water cooling section are connected in parallel onthe wind side, and the system wind resistance is low. Compared with otherwater-saving demisting towers, the fan power consumption is about 30% lower.

06/ High watersaving rate

The air cooling tube bundle is arranged onboth sides outside the tower, which can be expanded by increasing the quantityof fans in single tower and the area of air cooling tube bundle, so as to givefull play to the role of air cooling tube bundle and reduce water evaporation,and achieve a water-saving rate of 85% at most.

07/ Fogelimination throughout the year

The dry hot air passing through the aircooling tube bundle is mixed with the saturated wet air of the water coolingtube bundle to reduce its moisture content, and there will be no fog whenentering the atmosphere, so as to ensure the fog elimination throughout theyear.

08/ Intelligentautomatic control technology

The opening and closing of shutters of aircooling tube bundle and water cooling tube bundle, the frequency variation offan motor and the start and stop of spray water pump can be adjustedautomatically according to the inlet and outlet water temperature and ambienttemperature.

Client can choose to access the“Shuangliang cloud platform” developed by Shuangliang according to thecharacteristics of this product to upload the data to the cloud, which canrealize the functions of remote Internet real-time monitoring, WeChat receiptof fault information, cloud data backup, big data analysis, predictivemaintenance, equipment health analysis, etc.

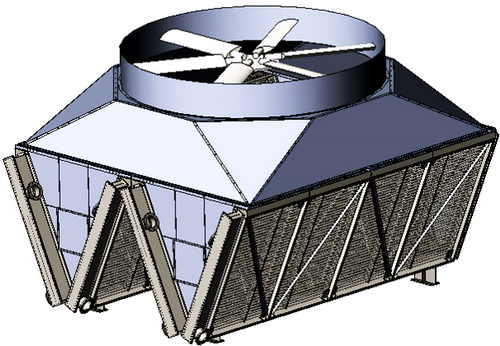

2.V Type Dry Cooling Tower

V Type Dry Cooling Tower can be useddependently or upgradation projects in combination with existing wet coolingtowers to save water consumption.

System composition

V separate water-saving and fog-removingsystem consists of finned tube bundle, circulating water pipeline and fangroup. V air cooler and mechanical ventilation water cooling tower are arrangedindependently and connected by circulating water pipe. The circulating water inwinter is cooled only by V type air cooler, no water vapor evaporates; thecirculating water in spring and autumn is cooled first by V type air cooler,then cooled by mechanical ventilation water cooling tower, and the amount ofwater vapor evaporates is less; the water cooling tower with mechanicalventilation is used in summer time with high temperature.

Main Features

01/ Modular, easy to install

V air cooler adopts self-supporting structure,modular design, easy and quick installation.

02/ Maintenance convenience

Tube bundle horizontal arrangement, removable coverplate tube box, easy to tube bundle internal cleaning and maintenance.

03/ High annual water savingrate

The circulating water is cooled only by the V typeair cooler in winter, without evaporation of water vapor; the circulating waterin spring and autumn is cooled by the V type air cooler, the cooling load ofthe mechanical ventilation water cooling tower is partial, the waterconsumption is low, and the annual water saving rate reaches 60%.

04/ Antifreeze property

Adopt special anti-freezing design, winter operationdoes not need to set blinds, anti-freezing safe and reliable.

05/ Separate layout

The V type air cooler is arranged independently fromthe mechanical ventilation water cooling tower. According to thecharacteristics of the site, all available space and flexible arrangement canbe made. If the area is tight, the V type air cooler can be arranged overheadon the road.

06/ Applicability

Suitable for water saving transformation of watercooling tower.

3.Mist Spray Dry Cooling Tower

System composition

The spray dry cooling system is composed ofstainless steel tube radiator, louver, circulating water system, expansionwater tank, spray cooling system, fan group and so on. The air cooling radiatoris arranged vertically outside the tower, which depends on the air to cool thecirculating water, but when the ambient temperature is high, water spray on theouter surface of the radiator is used to assist the cooling.

Main Features

01/ Low water consumption

In the whole year, only in summer hightemperature with short time spray cooling will apply, the annual water savingrate is more than 95%.

02/ Maintenance convenience

The radiator is arranged vertically outside thetower, which is only composed of air cooling radiator, fan system and closedcirculating water pipeline system. The maintenance equipment is less, and thereis no need for spray water quality management. The operation and maintenance issimple and convenient with less the operation and maintenance cost.

03/ Low operating cost ofcirculating water system

The circulating water system is a closed system withlow lift and low power consumption.

04/ Double Process Reverse CrossFlow Structure

The design of double flow reverse cross flowstructure makes the total heat transfer coefficient of air cooling radiatorhigher than that of single flow cross flow arrangement, and the total heattransfer area can be reduced by about 20%.

05/ Back-to-back arrangement,small footprint

One side air inlet and back-to-back arrangement areadopted to reduce the area, and the influence of hot air reflux is small.

06/ Applicability

Suitable for high effluent temperature (above 38℃) of circulating water.

Specify your requirements for tailored services (optional).