Solve the problem of high water consumption in power station

Applicable to water shortage areas, water saving > 85%

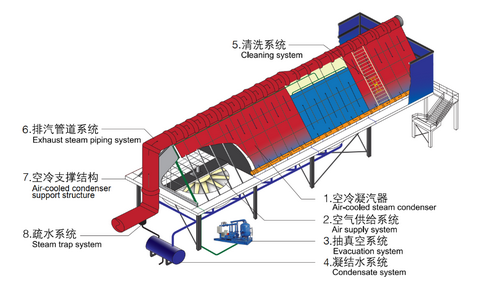

The ACC system is to distribute the exhaust steam discharged by the steam turbine directly to each unit condenser through the pipeline. The large axial flow fan inhales air, skims the tube bundle from the outside, and takes away the heat. The steam condenses into water and goes through the bottom header under the tube bundle to the condensate tank. The air evacuation system maintains the vacuum of the whole ACC system, so that the steam turbine can run normally and ensure the efficiency of power generation. The condenser is divided into parallel-flow tube bundle and counter-flow tube bundle. Most of the steam condenses in the parallel tube bundle, the non-condensable gas is extracted in the counter-flow tube bundles, and the parallel-flow and counter-flow tube bundles are connected through the condensate tank at the bottom. ACC has the advantages of less area, various anti-freezing methods and flexible arrangement.

1.Configuration and scope of ACC

Scope normally covers equipment and ducting from the outlet of the turbine low pressure cylinder to the inlet of the condensate pump, including:

1、Tube bundle

2、Air supply system

3、Air evacuation system

4、Condensate system

5、Cleaning system

6、Exhaust steam ducting system

7、Supporting structure

8、Draining system

9、Electrical system

10、Instrument & control system

2.Technical strength

1)Three test devices

Performance Testing Device for tube bundles

It is mainly used for heat transfer performance test of various finned tube bundle structures and on-line sampling test of finished products. The heat transfer coefficient and wind resistance of the tube bundle at different wind speed and the internal flow resistance of the tube bundle at different steam velocity are obtained by simulating several running back pressures of the steam turbine and testing the heat transfer performance and resistance loss of the tube bundle.At the same time, it is also used to verify the thermal performance of tube bundle and evaluate the actual performance of tube bundle

The unique environment test laboratory:1x4ACCwnvironment test device

The environmental laboratory can simulate the ambient temperature of 50℃~25℃, so it can simulate the summer working operating condition and winter operating condition of ACC. The summer condition is used to test the heat transfer performance of the tube bundle of the air-cooled condensing steam system, which provides the basis for the design of the actual air-cooled condensing steam system; The Winter condition is used to test whether the control program used to test the air-cooled condensing steam system in winter condition is effective for the anti-freezing protection measures of the system under the operating conditions such as starting, stopping and low load, and the minimum anti-freezing steam flow rate under different temperature conditions.

Full performance test bed:hot-state test device for one unit of 1000MW

The device can simulate the main operating conditions of the power station and is used to test the performance of the air condenser system, including: heat transfer performance, system reliability, stability, economy, especially the ability of full load operation in summer and the reliability of anti-freezing operation in winter

2)Nine fundamental researches

Shuangliang direct air cooled condenser system has realized the leap of ACC localization from theoretical research and development to engineering application . Nine basic research and development have filled many gaps in the industry and provided design support for the air cooling system of power station to be more in line with the national conditions of China.

1、Research on Heat exchange performance Transfer of Heat Exchanger Components

2、Research on resistance characteristic on Air Side of Heat Exchanger component

3、Research on resistance characteristics of steam side in Heat Exchanger Tube

4、Research on the atmospheric corrosion performance of Fins

5、Research on fouling performance of tube bundle

6、Flushing test of tube bundle fin

7、Anti-freezing test of tube bundle

8、 Numerical Simulation of Direct Air Cooling System

9、 Fatigue test of direct air cooled tube bundle

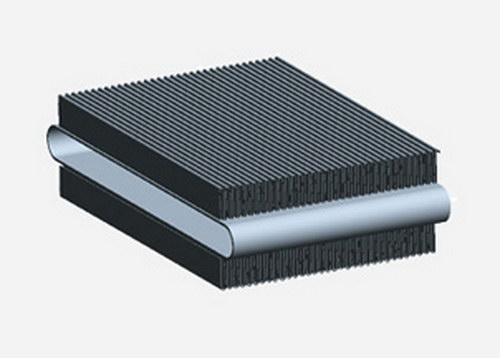

3.Single row tube

The single row tube is made by welding aluminum serpentine fin to large flat tube made of single side aluminum-cladding plate. Single row tube condenser have excellent heat transfer performance with below characteristics:

01/ High heat transfer efficiency

The heat transfer area on both sides of the tube bundle is fully utilized, and the steam side circulation area is large, the pressure loss is low, and the heat transfer efficiency is high.

02/ Strong corrosion resistance

The outer surface of the tube bundle is covered with aluminum alloy material with strong corrosion resistance, and the heat transfer fin of the tube bundle is also made of aluminum alloy material. Even after processing, the above materials will form an alumina protective layer immediately, thus obtaining good corrosion resistance.

03/ High strength, good cleaning ability

The tube bundle is welded by several single-row finned tubes and the tube plate, and the high strength integral structure is obtained, which is convenient for transportation and installation. Single row fin ventilation channel is linear, easy to flush, can be washed with high pressure water, without deformation.

04/ Good anti-freezing performance

The section of the base pipe has a large ratio of length to width, and the flow of condensate water is more smooth, which reduces the over-cooling of condensate water and the danger of freezing pipe in winter.

Specify your requirements for tailored services (optional).